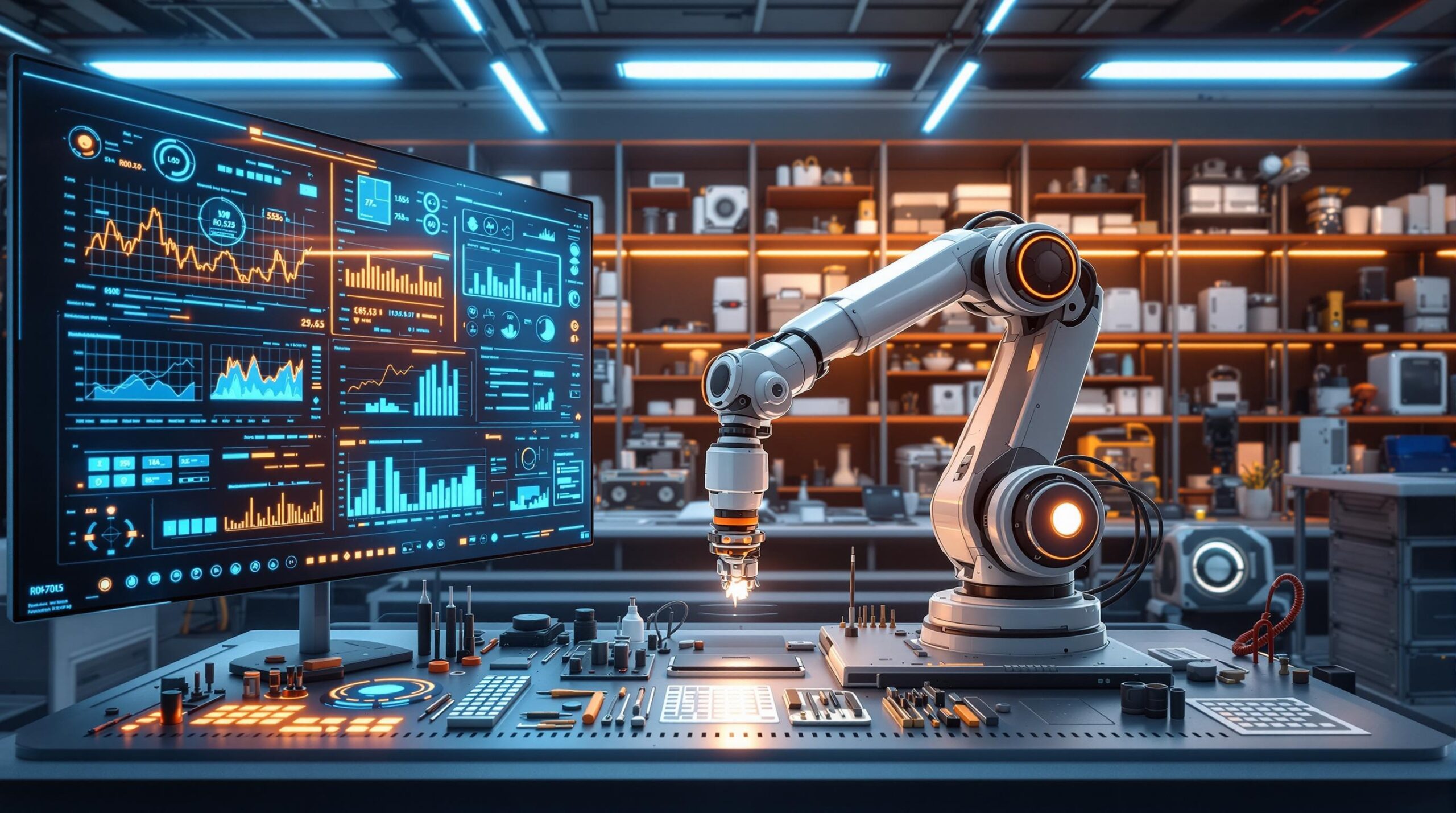

Anticipating failures before they happen

Unexpected downtime is one of the biggest challenges in manufacturing. We help industries transition from reactive maintenance to predictive models using IoT sensors, machine learning, and remote monitoring. Our solutions detect problems before they become costly failures, extending equipment lifespan and ensuring continuous operations.

How we help

- Deploy IoT sensors across critical equipment.

- Build predictive algorithms that detect anomalies early.

- Enable remote dashboards for real-time machine monitoring.

- Deliver contextual alerts and recommendations for proactive actions.

Key Features

IoT-enabled Monitoring

Continuous tracking of equipment performance

Predictive Alerts

Notifications on anomalies before breakdowns occur.

Operational Continuity

Reduce downtime and keep production on track.

Cost Optimization

Lower maintenance costs and extend asset life.